E-Mail-Formatfehler

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Nachrichten

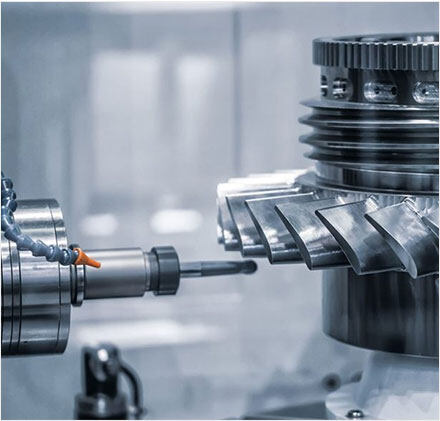

These Devices make Precision Machining Possible

In recent years, the global machinery manufacturing technology has developed rapidly, and the market requirements for production efficiency and workpiece accuracy are also improving year by year. However, most of China's mold processing enterprises are not equipped with precision processing airports, so they can only rely on low prices as a competitive weight, and their development is like walking on thin ice.

If machining enterprises want to stand out in the highly competitive industrial market, they need to skillfully use precision processing technology. If the processing technology stagnates, the efficiency and quality of the factory's processing workpieces will naturally not be improved, and the products they produce will always be at the low-end level. They will never be able to move towards the high-end manufacturing industry, and will naturally be eliminated by the constantly changing and innovative manufacturing market.

Leading technologies in the field of precision machining

Generally speaking, the accuracy of machining workpieces is an important measure of the market competitiveness of machining enterprises. At present, the more advanced precision machining technologies on the market include the following:

CNC milling

High-speed milling adopts a small-diameter milling cutter, with high speed (spindle speed can reach 40000 RPM) and small circular feed, which greatly improves the production efficiency, and the accuracy can reach 5 μ m; At the same time, due to the small milling force, the thermal deformation of the workpiece is reduced, the milling depth is small, the feed is fast, and the surface finish can reach RA <0.15 μ m.

Slow wire cutting processing

Slow wire cutting is mainly used for the precision processing of various parts, which is a high-precision processing method. High-end cutting machine tools can reach less than 3 μ M, and the surface roughness can reach ra0.05 μ m. At present, the automatic threading and cutting of electrode wire have been realized, and the actual cutting efficiency can reach about 200 mm2 / min.

EDM

EDM is suitable for machining complex parts, such as precision small cavities, narrow slits, grooves, corners, etc. When the machining area is less than 20 square centimeters, the EDM machine can achieve RA <0.1 μ M mirror EDM, uniform frosted surface, and various levels of surface treatment. For fine parts such as connectors, the annular clearance is less than 0.02mm, and the machining accuracy is 5 μ Within M.

Grinding machine processing

A grinding machine is precision equipment used for the surface finishing of parts. Grinding head vertical feed min. 0.1 μ m. Grinding surface roughness Ra <0.05 μ m. The machining accuracy can be controlled within 1 μ Within m, ultra-precision grinding can be realized. Taking the optical curve grinder of Tiantian in Japan as an example, the maximum spindle speed can reach 30000 rpm, and the machining accuracy is 2 μ Within m, the minimum inner R angle is r0.03mm, and the outer R angle is r0.02mm. The thinnest part can reach 0.06mm, the depth diameter ratio of the machining groove is about 2:1, and the surface roughness Ra can reach 0.025 μ m.

Development trends in the precision machining industry

At present, with the industrial upgrading and adjustment, the manufacturing industry has entered a stage of rapid development. The emerging precision machining technology has become an important means to control the accuracy of machining workpieces.

High-precision

The eternal theme of precision machining technology is high efficiency and high precision. The accuracy indicators are constantly moving forward in the sub-nanometer, nanometer, and deep sub-micron levels, and the machining accuracy is still continuously improving. At present, many precision machining technical indicators have been based on nano, and are still developing in the direction of breaking through the nano boundary.

Intellectualization

At present, in precision machining technology, the process control method and control strategy is one of the research hotspots. The efficiency and stability of machining are directly related to the intelligence of precision machining equipment. And through the continuous introduction of intelligent equipment, reducing the dependence of processing results on human experience has long been a major goal in the manufacturing field. At the same time, the microdevices needed in the fields of optoelectronic information, microelectronic machinery, and the need to establish large-scale precision parts and ultra-precision processing equipment in aerospace, aerospace, and other fields all have high requirements for their intellectualization and automation.

The parts form a whole. Only when the accuracy of each workpiece is improved can the overall quality of the product be improved. Precision machining technology can be said to be the decisive factor for the modern manufacturing industry to enter a new stage of high-end creation from low-end manufacturing. It is also the key technology to winning in international competition.

For more information about large precision machining, elite precision machining, plastic precision machining, plz feel free to contact us.